IoT use cases in manufacturing: The best way to make factories more efficient and save money.

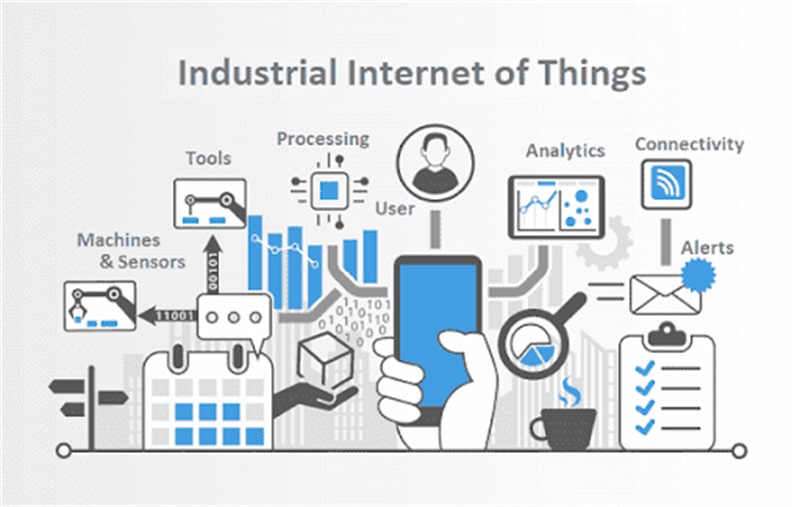

The Industrial IoT is an emerging technology that promises to revolutionize industries' operations. The industrial internet of things (IoT) is a system of interconnected devices, machines, and people that collect and share data. Industrial IoT applications aim to increase efficiency and productivity by reducing downtime, errors, and waste.

Industrial IoT Market Overview

The industrial IoT market is awaited to grow from $947.48 billion in 2020 to $1,562.87 billion by 2025 at a compound annual growth rate (CAGR) of 10.4% during the forecast period (2020-2025).

The major drivers for the growth of the industrial IoT market are the increasing demand for operational efficiency and asset utilization and the need for real-time data analysis. The key factor restraining the growth of this market is the lack of standardization and interoperability of technologies.

Top 5 Industrial IoT Use Cases

IoT is revolutionizing the industry's work. Yalantis helps manufacturers increase their production line's efficiency through real-time data collection and analysis. By monitoring all aspects of the production process. Yalantis's article also provides insights that can help identify issues and optimize workflows.

IoT manufacturing use cases are vast and varied, but a few stand out as particularly transformative for the industry. Here are the top 5 industrial IoT use cases:

Quality Control and Tracking

Quality control and tracking are among the most important industrial IoT use cases. By connecting devices and sensors to the internet, manufacturers can track the quality of their products in real time and make necessary adjustments to ensure that only the highest quality products are delivered to customers. This reduces waste, improves customer satisfaction, increases efficiency, and lowers production costs.

Predictive Maintenance

Predictive maintenance is an industrial IoT use case that can help organizations save money and increase efficiency. By collecting data from sensors and other devices, predictive maintenance can provide insights that allow organizations to take proactive measures to prevent issues before they occur. Predictive maintenance can also help organizations improve their productivity by reducing downtime.

Energy Management

As industries have become more reliant on technology, the need for better energy management has increased. Energy management aims to ensure that industrial facilities use energy efficiently and reduce their environmental impact. There are several ways to achieve this, but industrial IoT devices are the most effective.

Industrial IoT devices can be used to monitor a variety of different aspects of energy usage. For example, they can track the amount of electricity consumed by different equipment. They can also monitor environmental conditions such as temperature and humidity. By monitoring these factors, it's possible to make adjustments that can lead to significant reductions in energy consumption.

In addition, one can use industrial IoT devices to control. For example, they can automatically shut off equipment when it's not needed or during a power outage. They can also regulate the flow of electricity between different parts of a facility. Doing so makes it possible to keep critical systems running while reducing overall energy usage.

Asset Tracking

Asset tracking is one of industrial IoT's most popular use cases, as it can provide valuable insights into utilizing physical assets. Organizations can optimize maintenance schedules, reduce downtime, and improve safety by tracking the location and status of equipment.

In many cases, asset tracking is accomplished through the use of RFID tags. These tags can be read by sensors placed throughout a facility, allowing for real-time tracking of individual assets. In other cases, GPS tracking devices may be used to track the location of vehicles or other mobile assets.

Organizations can also use asset tracking data to monitor trends and better understand how their assets are used. This information can be used to make future purchases or adjust maintenance and repair schedules.

Workforce Optimization

The industrial sector is constantly pressured to improve operational efficiencies and optimize workflows. With the rise of the IoT, there is great potential to further optimize the workforce by connecting various devices and machines to gather data that can be used to improve performance.

For example, sensors can be placed on machines to monitor usage and output, while connected devices can track employee whereabouts and job progress in real-time. This data can then be analyzed to identify areas of improvement, such as where bottlenecks are occurring or which employees may need more training. This way, the IoT can help companies streamline their operations and make their workforce more productive.

The Benefit of Industrial IoT

The IIoT in manufacturing can help bring many benefits to businesses and organizations. These include:

- Increased efficiency and productivity: By connecting devices and machines to the internet, businesses can collect data more efficiently and make better decisions that lead to increased productivity.

- Cost savings: With improved data collection and analysis, businesses can save money by reducing waste and increasing efficiency.

- Improved safety: By monitoring devices and machines, businesses can identify potential safety hazards before they cause accidents or injuries.

- Enhanced customer experiences: By collecting data about how customers use products, businesses can improve the design and function of their products to better meet customer needs.

- New business opportunities: The industrial IoT creates new opportunities for businesses to develop innovative products and services that generate new revenue streams

Conclusion

The future of IoT is looking very promising. Many industrial internet of things companies are working on making this technology a reality, and it is only a matter of time before widespread adoption.

The benefits of Industrial IoT are many and varied, but the most important is that IIoT can help you optimize your business processes and improve your bottom line.